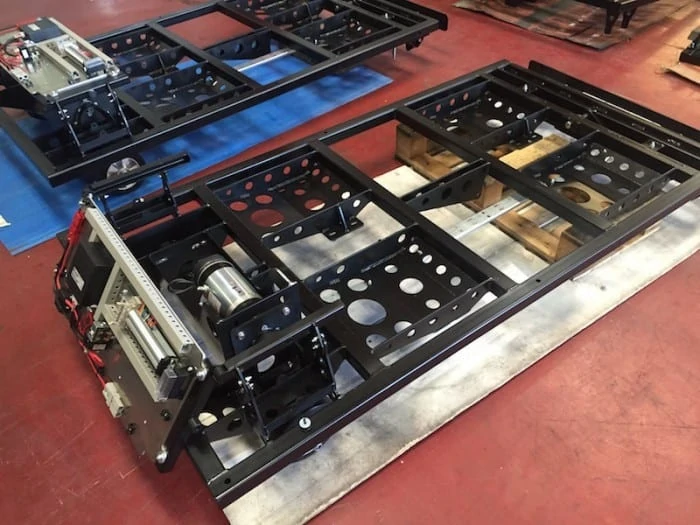

In the last post, we talked a lot about the little engineering details that we focus on. Well in this weeks instalment, we have a beautiful example of this in action. Our experience of getting in and maintaining and mending rides in theme parks all over the world, means that when we come to design them, we always ensure that life will be made easier for the teams behind us who will be looking after them. So, when we designed the chassis of this ride we thought about this a great deal. You can see in the next three images how the control panel, that is normally buried deep within the bodywork, slides out and down for easy access. It makes life so much easier in the long run and just takes a little more thought at the design stage.

Control boards fitted to the chassis in their closed position

And then fold down for super easy access for maintenance – bear in mind this would normally be buried inside a ride body

The motors and gearing we have designed have now also arrived and are being test fitted. They have been designed to last for years and years with absolutely minimum maintenance.

And again in the last article, we saw the arrival of the parts for the Control Box. They came in on a Pallet and the team were on them straight away. This has now been completely finished. Essentially this box brings in single phase 240v power and steps it down and converts it 48v DC to put power to the rails and drive the cars. In the third photo below, you’ll see there is also a large bank of capacitors which smooths the power delivery to ensure it runs cleanly with no nasty power spikes. All clever stuff, but again the team designed that in from the outset.

Inside you can see the single phase transformer and the rectifier by its side

Inside the control box with the capacitor bank fitted too

The last piece to fit is to the long black handle like things that stick out from the boards that you can see in the image above. This is to hold a transparent cover to ensure absolute safety and neatness for the job.

At Garmendale, we love these little details – for us they are what makes the difference to long term ownership of a ride system. The cars for this one have now arrived and look amazing, but we aren’t showing them yet. If you want to see the big unveil of that, you’ll need to join us at EAS in Barcelona, stand 833 on September 20-22nd and shortly afterwards, here on the blog.

+44 (0)115 932 7082

+44 (0)115 932 7082 enquiries@garmendale.co.uk

enquiries@garmendale.co.uk